Why “Simple” Metal Details Are Often the Hardest to Fabricate

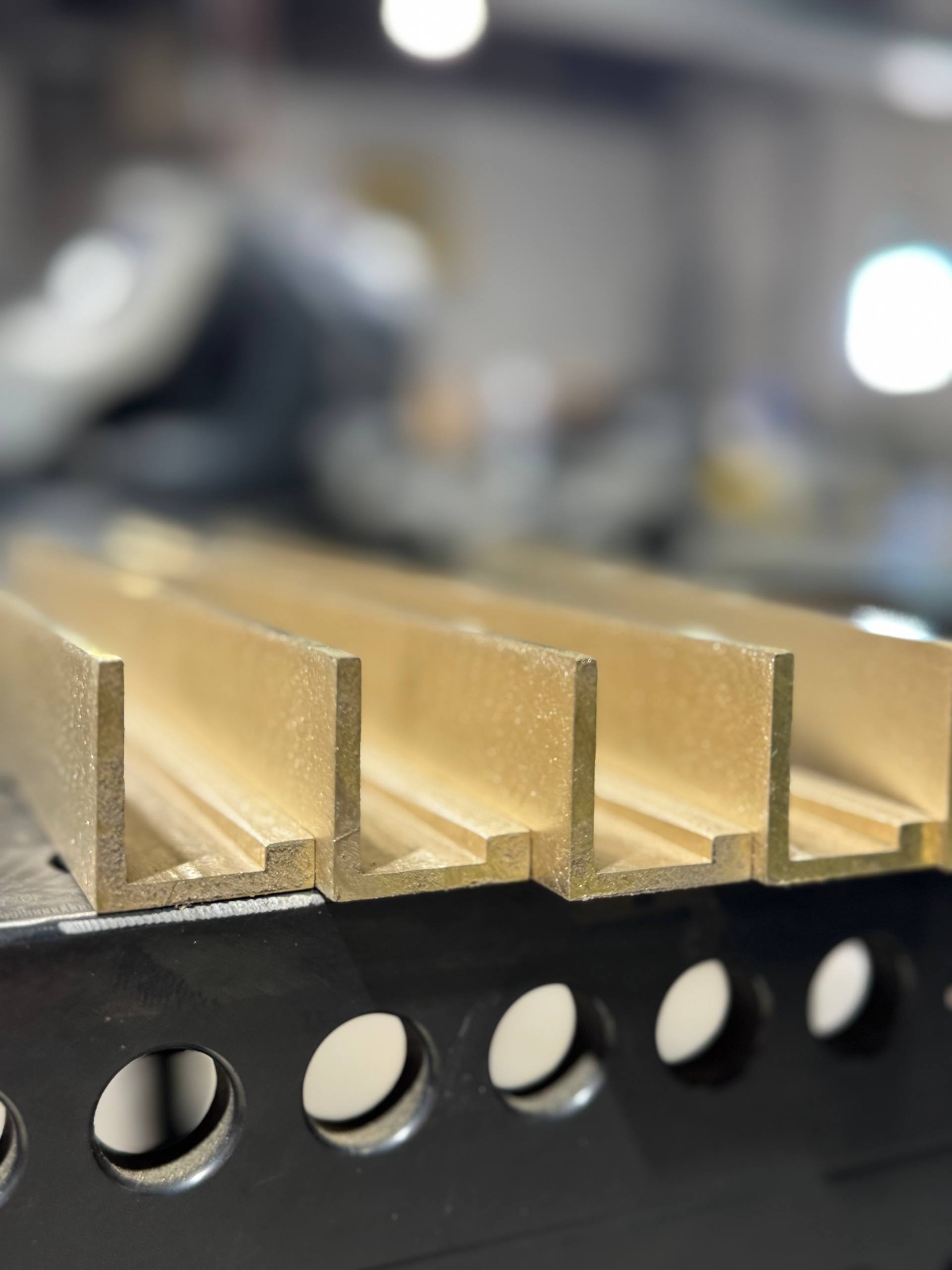

Simple metal details are often perceived as easy to design and fabricate because they appear clean, minimal, and straightforward. However, in architectural metal fabrication, these minimal elements are frequently the most complex and demanding to execute successfully.

Minimalist metal design removes visual noise and decoration. As a result, every line, joint, reveal, and surface finish becomes highly visible. This lack of visual distraction means that fabrication precision, coordination, and execution standards must be exceptionally high.

Minimalism Leaves No Room for Error

In more decorative or layered metal designs, minor imperfections can be absorbed by texture, pattern, or complexity. By contrast, simple metal details expose everything.

Because of this:

-

✔ Even small misalignments become obvious

-

✔ Slight variations in flatness are immediately noticeable

-

✔ Welds, seams, and transitions must be nearly invisible

Therefore, what appears “simple” on a drawing often demands more labor, tighter quality control, and greater fabrication expertise than visually complex work.

Tight Tolerances Are Critical in Simple Designs

Minimalist metal details depend heavily on precision. Common requirements include:

-

✔ Flush connections

-

✔ Consistent shadow gaps

-

✔ Sharp, uninterrupted lines

-

✔ Perfect alignment between adjacent materials

To achieve these outcomes, fabricators must work with very tight tolerances, often much tighter than those used in conventional metal fabrication. However, tight tolerances increase complexity across every stage of the process—from cutting and welding to finishing and installation.

Even small deviations can compromise the final appearance, making tolerance management a central challenge in minimalist metalwork.

Hidden Fasteners Increase Fabrication Complexity

One hallmark of simple metal details is the absence of visible fasteners. While this creates a clean aesthetic, it significantly increases fabrication difficulty.

Hidden fastening systems often require:

-

✔ Custom brackets and substructures

-

✔ Precise coordination with substrates

-

✔ Limited installation tolerances

-

✔ Advanced planning before fabrication begins

Moreover, concealed connections leave no opportunity for adjustment once installed. As a result, shop drawings, coordination, and mockups become essential to avoid costly revisions in the field.

Flatness Is Harder Than It Looks

Large, flat metal surfaces are a common feature of minimalist architecture. However, achieving true flatness in metal is inherently difficult.

Metal naturally wants to move due to:

-

✔ Welding heat

-

✔ Internal stresses

-

✔ Temperature changes

Without careful planning, these forces can lead to oil-canning, waviness, or distortion. Consequently, fabricators must carefully select material thicknesses, welding sequences, and reinforcement strategies to maintain flatness—often increasing cost and lead time.

Finish Quality Becomes More Critical

In simple metal details, finishes are no longer secondary—they are the design. Scratches, swirl marks, or inconsistencies that might be acceptable in decorative work become unacceptable in minimalist applications.

As discussed in many architectural case studies published on platforms like ArchDaily, minimalist architecture demands a higher level of craftsmanship because materials are expected to perform visually without concealment.

Therefore, finishing processes such as grinding, polishing, brushing, or patination must be executed with exceptional consistency and care.

Coordination Matters More Than Aesthetics Alone

Simple metal details often intersect with other materials such as glass, stone, wood, or concrete. These transitions must be clean, precise, and predictable.

This requires:

-

✔ Early coordination with other trades

-

✔ Accurate substrate conditions

-

✔ Clear responsibility boundaries

Without this coordination, even perfectly fabricated metalwork can fail to meet design expectations once installed.

Why “Simple” Usually Means “More Expensive”

Because simple metal details demand:

-

✔ Tighter tolerances

-

✔ Higher-quality finishes

-

✔ More coordination

-

✔ Greater fabrication time

They are often more expensive than complex-looking alternatives. This reality can surprise clients and designers who associate minimalism with efficiency or cost savings.

However, the cost reflects the level of precision and control required, not the visual complexity.

Simple metal details are not simple to fabricate. On the contrary, they represent some of the highest levels of craftsmanship in architectural metalwork. Minimalist design amplifies every decision, every joint, and every surface.

Understanding this complexity helps architects, designers, and clients set realistic expectations, make informed decisions, and achieve the clean, refined results that minimalist architecture demands.

See more

- Trending Metal Finishes for 2024: What’s In and How to Use Them

- Architectural metal work vs. Industrial metal fabrication: What’s the real difference?

- Top Trends in Architectural Metal Design for 2024

- Custom High-End Metal Features that Elevate Luxury Interiors: A Design Guide for Custom Home Builders and Interior Designers

- The Versatility and Elegance of Metal and Glass Partition and Decorative Walls

- Luxury in the Details: Small Metal Accents That Make a Big Statement